CNC Foam Cutter Machine

Using a 4-axis CNC foam cutter machine for manufacturing can result in consistent, high-quality products that are custom-designed to meet specific requirements. The use of CNC machines can also increase efficiency, reduce costs, and reduce lead times, making it a cost-effective solution for producing custom foam parts.

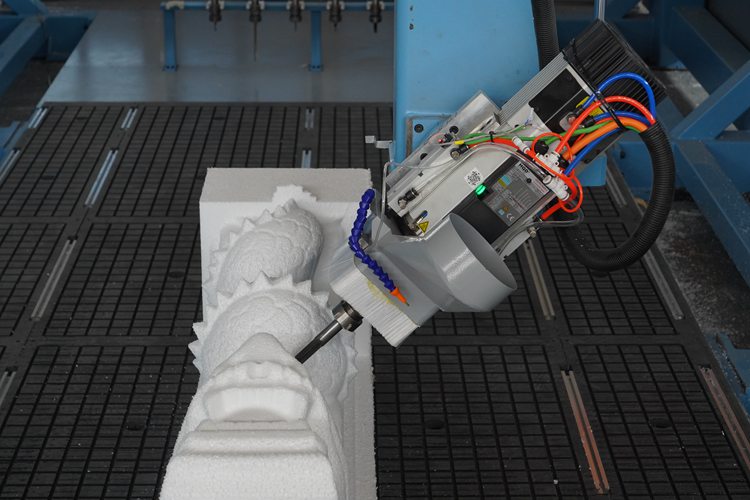

4-axis foam CNC router is a type of computer numerical control (CNC) machine that is designed for cutting and shaping foam materials. It has four axes of motion, which allows it to move the cutting tool in four different directions: X, Y, Z, and A.

Advanced Performance

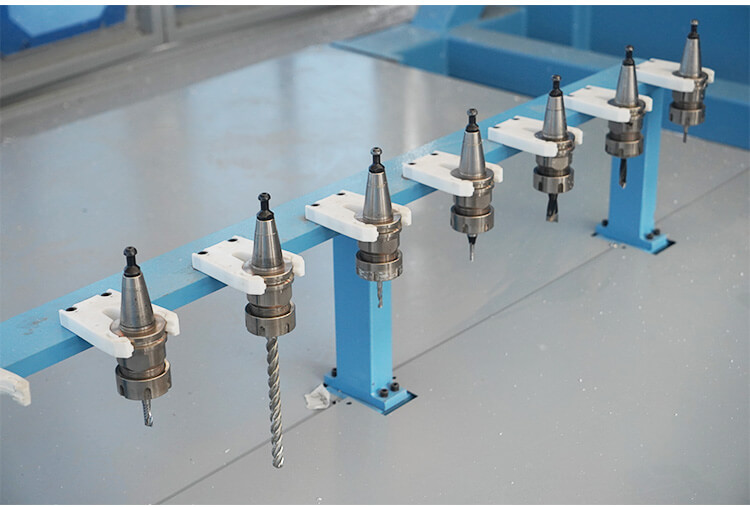

Linear Automatic Tool Changer

With the function of linear automatic tool changer, it make the whole processing more time-saving and more efficient.

Air Cooling Spindle

Equipped with HSD air cooling spindle with imported bearing, it has many advantages like long service life, low noise, and strong cutting ability.

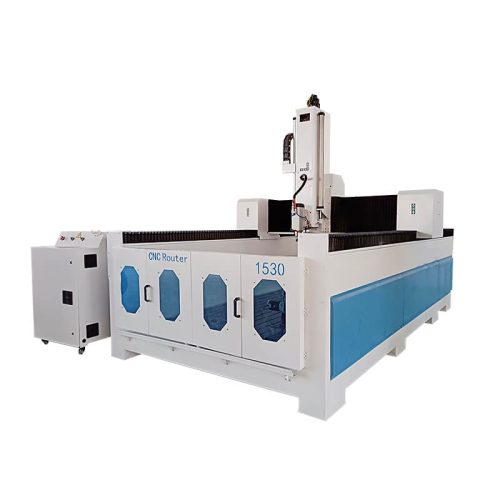

Worktable Optioned

There are many choices of table size: 1300*2500mm, 1500*300mm, 2000*4000mm, (we can customize the size according to your needs)

Control System Optioned

Taiwan LNC SYNTEC system is the standard system.

Product Parameter

| Model | iGW-MC-1530 |

| Working area | 1500*3000*800mm |

| Transmission | X/Y rack and pinion, Z ball screw |

| Table structure | Aluminum profile |

| Spindle power | HQD 9KW |

| Spindle speed | 18000rpm/min |

| Travelling speed | 45m/min |

| Working speed | 30m/min |

| Working Delicacy | 0.02mm |

| Repositioning Accuracy | 0.03mm |

| Driver motor | Servo motor |

| Control system | DSP/Nc studio /Syntec |

| Voltage | 3 Phase/380V/50HZ |

Samples

CNC Router 4 Axis Machining Centre

Mold industry: casting mold, automobile, ship, yacht, aviation industry, rail transportation etc.

Musical instruments: large 3D curved surface and shape processing.

Applicable materials: wood, EPS, other non-metal carbon mixed compound, etc.

Reviews

There are no reviews yet.