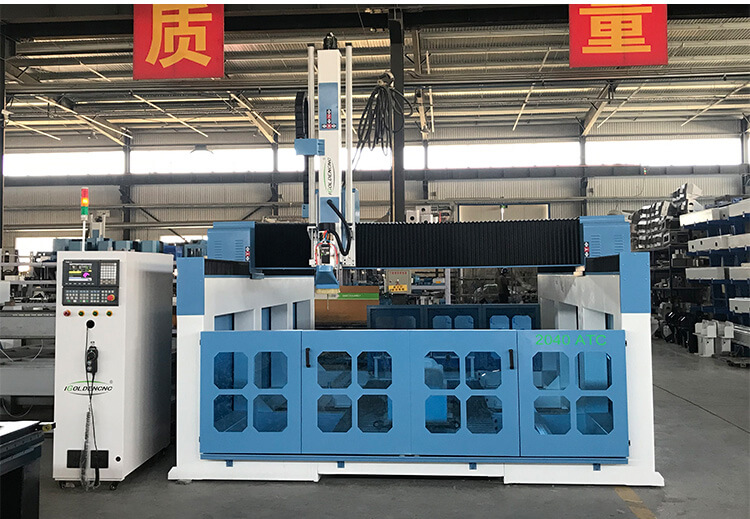

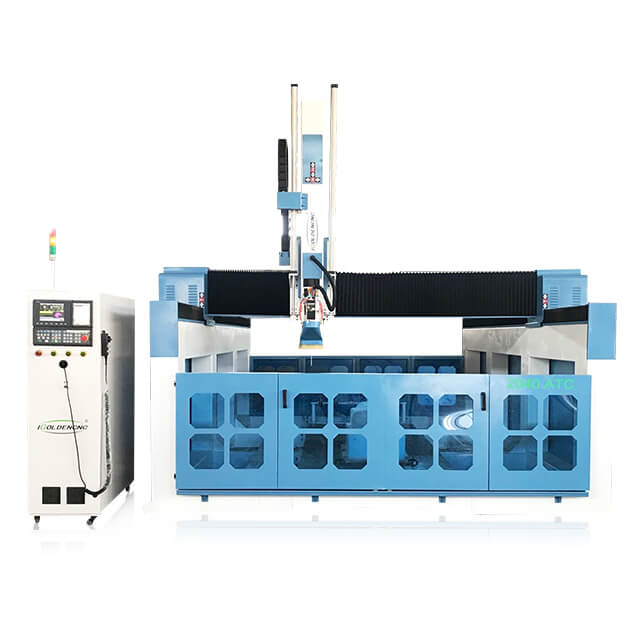

4 Axis Foam CNC Router

EPS/foam CNC router usually comes with a big working dimension for carving and cutting large-size workpieces of wood, aluminum, and styrofoam. It can also be equipped with an ATC spindle and a rotary device for complex, heavy-duty, and long-term work. It is widely used to process and carve wood and styrofoam automotive, ship or other molds, and GRG or GRC decorations, and architecture models.

4 axis CNC router is quite good at processing 3D workpieces. It generally falls into two types. The first type described hereunder is equipped with a rotating spindle that can swing by 180°. It can engrave 3D patterns and drill holes on side surfaces of wood, MDF, acrylic, foam, rubber, and other materials. For example, 3D letters, signs, reliefs, and sculptures.

Advanced Performance

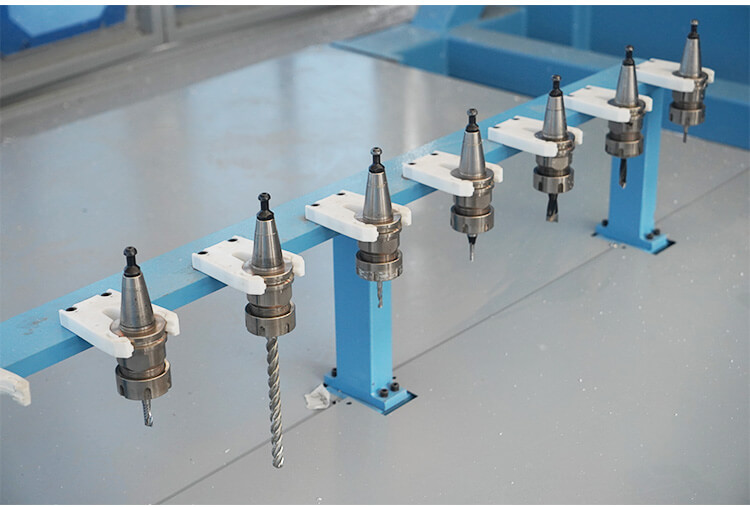

1.Using straight line in knife knife library design, in the process of machining can be automatically replaced, greatly improving the work efficiency.

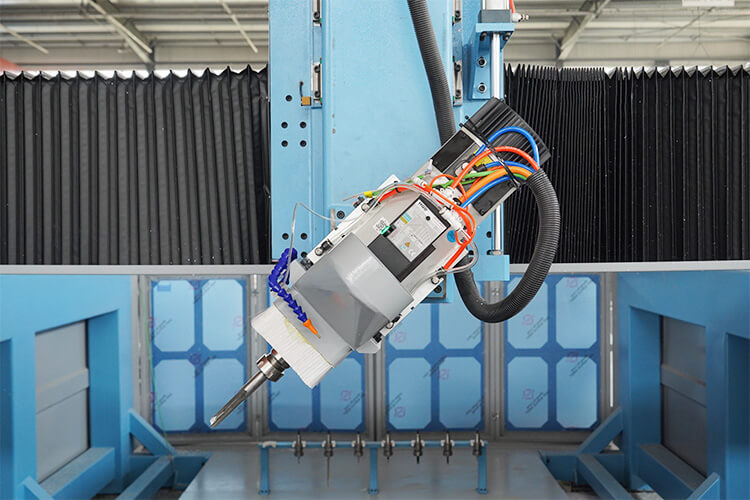

2.Adopts 9.0 kw air-cooled automatic tool change spindle he, long life, low noise, reliable in quality.

3.IGOLDENCNC independent electric control cabinet, humanized design, Taiwan Syntec system, the operation is simple and convenient.

4.Adopt Taiwan guide rail and the new moon of silver rack, high positioning accuracy, slide smooth, reliable quality, long service life.

5.The worktable rotating device specially designed for sinking worktable has a thimble structure at both ends.

Product Parameter

| Model | iGW-MC-2040 |

| Working area | 2000*4000*900mm |

| Spindle | HQD 9.0kw ATC air cooling |

| Speed Speed | 18000rpm |

| Repositioning Accuracy | 0.02mm |

| Machine Body | Square Tube Welding Structure |

| Guide Rails | Taiwan HIWIN |

| Driver | Japan YASKAWA Servo Drive and Servo Motor |

| Reducer | Japan SHIMPO |

| Worktable | Aluminum profile +PVC |

| Inverter | Fuling |

| Electrical Components | France SCHNEIDER |

| Control System | Syntec |

| Voltage | 3phase 380V/50HZ |

Samples

Hot applications include:

Carving all kinds of non-metal materials processing such as foam, lost foam, automobile foam mold, yacht mold, large ship wooden mold, cast wooden mold, engineering plastic materials, aviation wooden mold, propeller, train wooden mold, etc.

>Foam processing of automotive stamping molds, casting wood molds, automotive interiors, processing of engineering plastic materials;

>Other industry molds: electrical appliance molds, lighting molds, ceramic sanitary ware, three-dimensional curved surfaces for large musical instruments, instrument molds, home appliance molds, air-conditioning molds, automotive molds, automotive interior molds, etc.

Reviews

There are no reviews yet.