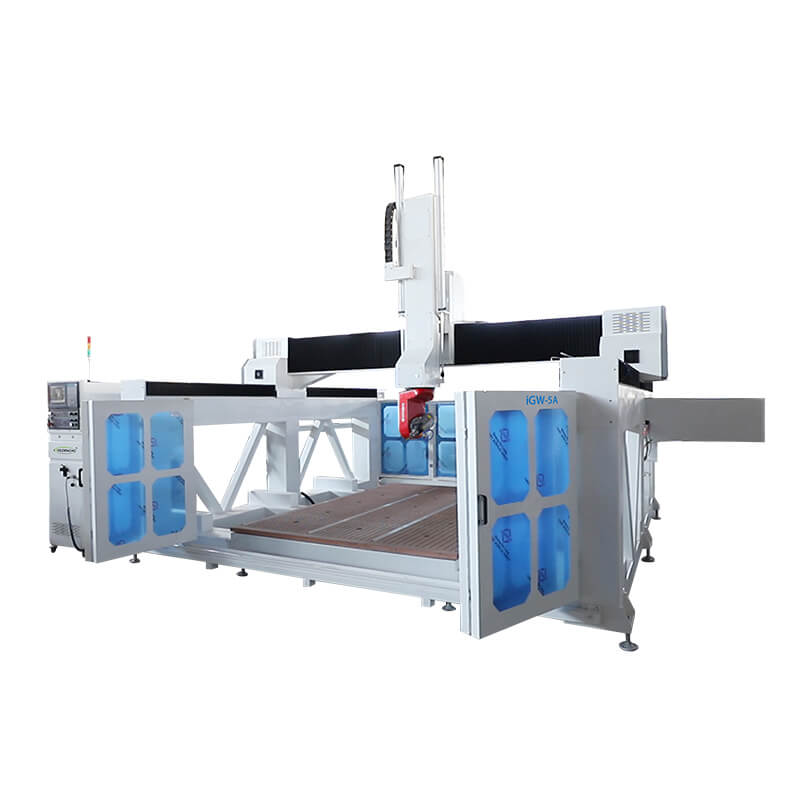

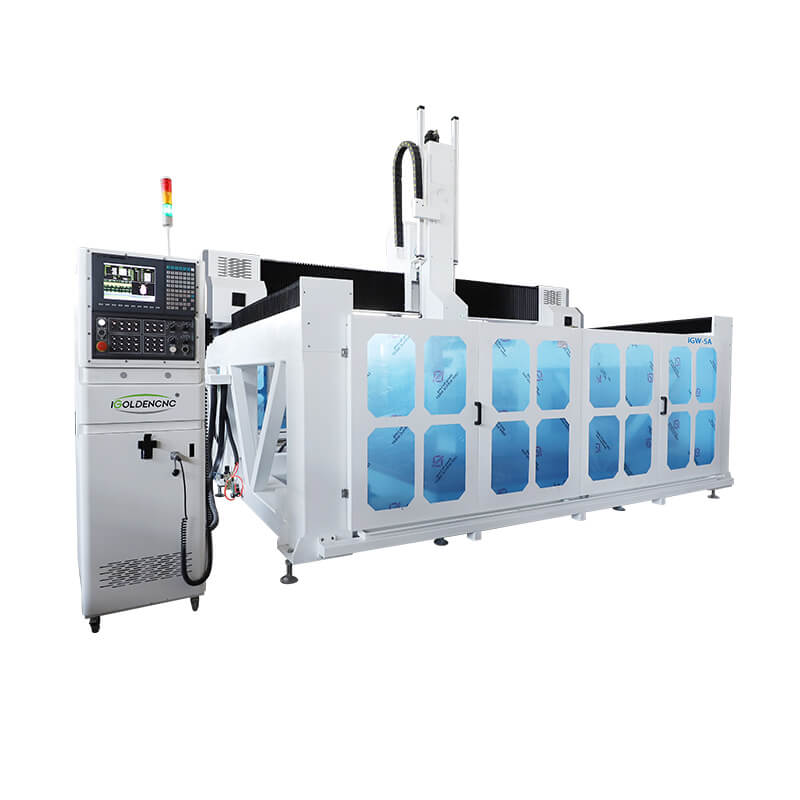

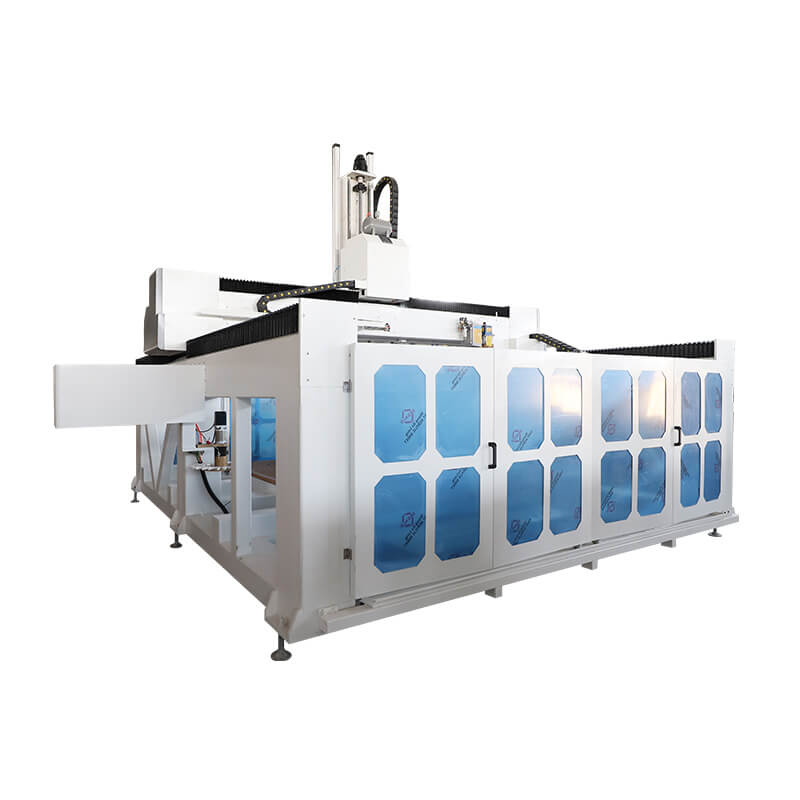

5 Axis CNC Router and Milling Machine

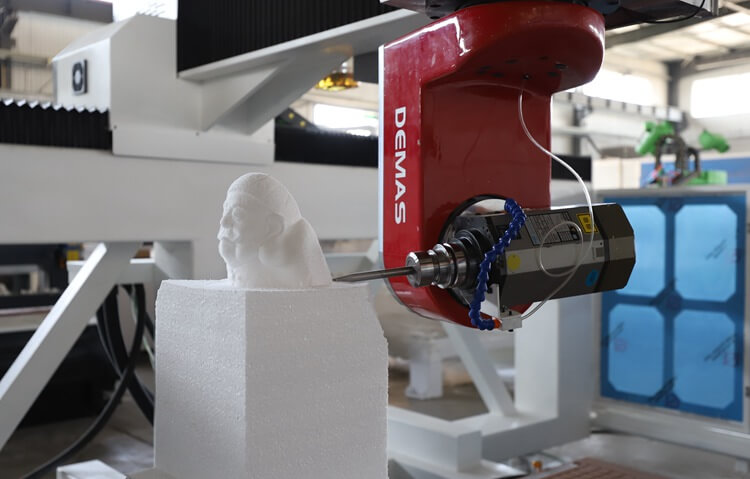

Due to the flexibility of the iGOLDENCNC 5 axis cnc machining centre, it is commonly used for mold making, machining moulds in wood, resin tooling board, EPS and composites, trimming of vacuum formed mouldings, plastic fabrication, GRP machining, props and model making, profiling, solid surface machining and contouring, various large metalloid mould.

5 axis CNC machine is designed to deliver high speed and highquality cuts for a wide range of materials, including but are not limited to wood, plastics, non ferrous metals and other composites.

Advanced Performance

Product Parameter

| X, Y Axis Working Area | 2000*3000mm |

| Z Axis Working Height | 600-1200 optionedmm |

| Positioning Accuracy | 0.03mm |

| Re-positioning Accuracy | 0.02mm |

| Body Structure | Welding Body |

| X, Y Axis Structure | Linear Guide Rail, Gear Rack |

| Z Axis Structure | Linear Guide Rail, Screw |

| Max. Running Speed | 60000mm/min |

| Max. Working Speed | 30000mm/min |

| Spindle | 14kw ATC Spindle(Optioned) |

| Spindle RPM | 24000rpm/min |

| Working Voltage | AC 220V/ 380V±10%,50-60Hz |

| Machine Weight | 2300kg |

We offer customized services according to your requests such as the working area and specifications.

Samples

Application of 5 Axis CNC Router Machine

The 5 axis woodworking cnc router with ATC function, it’s easy to accomplish full set processing of complex parts from milling, slotting, drilling, sawing, mortise, mortise, etc, the advanced model designed by iGOLDENCNC, combined with a competitive set of configurations.

Mold industry: 5 axis processing of FRP wood mold, casting wood mold, resin products, sludge model and various non-metal molds;

Ceramic sanitary industry: 5 axis processing of gypsum molds, 5 axis processing of various gypsum products;

Furniture industry: 5 axis processing of solid wood furniture, 5 axis processing of various furniture tenon and mortise pieces, 5 axis processing of stair elbows, and 5 axis processing of various furniture.

Reviews

There are no reviews yet.